Use cases

Where AI best fits in the engineering workflow.

Artificial intelligence (AI) in engineering use cases from Monolith.

Get in Touch

Key benefits of AI in the engineering workflow today

Reduce expensive & labour-intensive testing.

Decrease risks to product performance & quality.

Shorten product development duration significantly.

Four ways to use AI to cut validation costs

Build shorter test plans, create fewer prototypes, find errors faster, and validate designs more quickly using AI-based self-learning models.

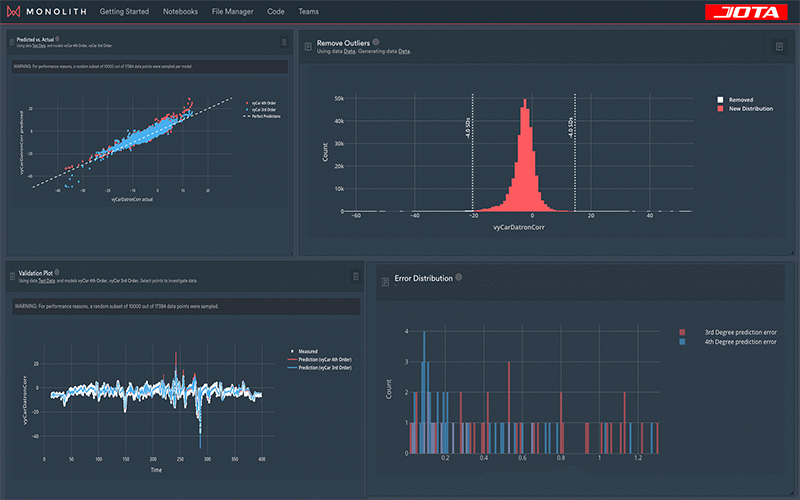

1. Automatically detect faulty sensors

To avoid downstream issues, your engineers must tediously inspect test data for errors. One failed sensor or wiring malfunction can render thousands of dollars in testing useless.

- Prepare your data for optimal AI performance

- Catch bad data now so you avoid re-engineering later

- Find outliers in your test data fast with intuitive visualisation

2. Predict the critical tests to run

Test too much and you waste time confirming what you already know. Test too little and risk missing performance issues. Schedule, quality and your career depend on finding the balance.

- Run the most important tests and skip the rest

- Optimize resources spent on costly test rigs and facilities

- Validate your designs faster with fewer prototype iterations

3. Determine the cause of system failure

Product design issues during validation risk launch delays and lost market share. Pressure on engineers is high to identify critical parameters causing failure, quickly analyze the root cause, and predict how the product will perform in changing conditions.

- Predict what design changes will most likely fix the failure

- Identify components causing sub-optimal performance

- Avoid long delays and uncertainty in the validation process

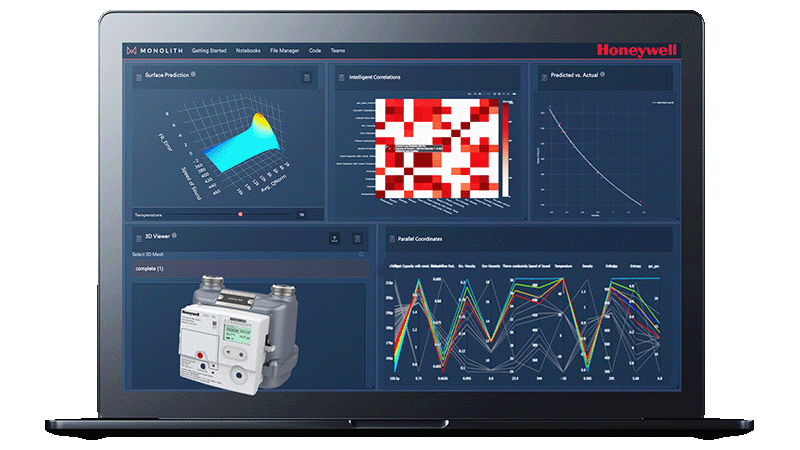

4. Calibrate for thousands of conditions

Designing highly complex, non-linear systems that must meet stringent performance standards is challenging. Predicting which combination of inputs will deliver the optimal output, in all operating conditions, is next to impossible.

- Calibrate complex dynamic systems

- Ensure your system performs to spec in all conditions

- Find best-fit values across 1000's of inputs and conditions

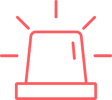

Identify an AI use case

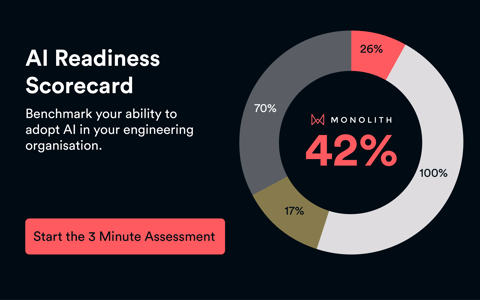

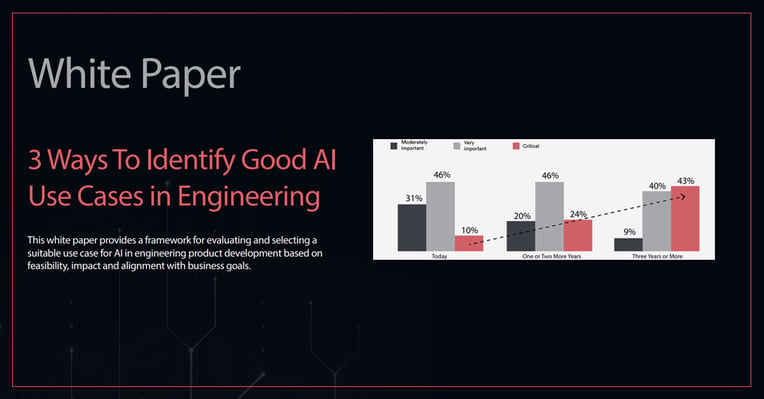

3 ways to identify good AI use cases in engineering

Learn how you and your team of engineers can unlock the full potential of AI and transform your product development workflows, ultimately leading to greater success in an increasingly competitive marketplace.

No code software

AI built by engineers for engineers

- Avoid wasted tests due to faulty data

- Build just the right test plan - no more, no less

- Understand what drives product performance and failure

- Calibrate non-linear systems for any condition

_4_w_66165a.png)